Supplying former ‘Power Isolated Island’

Field test provides blueprint for future de facto survey method

Located in the South China Sea, Hainan Island is the smallest province of China and is the nation’s southernmost point. It is renowned for tropical climates, beach fronts and its wild mountainous inlands. In the city of Sanya, a tourist hot-spot, sits an array of luxury hotels alongside the attractive Yanoda Rainforest hiking trails, suspension bridges and waterfalls. Geographically, Hainan Island is separated from Guangdong’s mainland Leizhou Peninsula by the Qiongzhou (Hainan) Strait, a body of water and the main terminal of travel from island-to-mainland.

Hainan Island was once known locally as the ‘Power Isolated Island’ as all power was controlled and delivered from the island itself. However, the Fukang Line (power cables) were laid in June 2009 from mainland across the Qiongzhou Strait, to the island in order to back up the entire Hainan island power supply. The role of this four-cable line was fundamental to ending the ‘Power Isolated Island’ tag as it is now responsible for the whole island’s power as a backup should there be a grid collapse in the on-island power supply network.

The Fukang Line requires an annual root survey to assess the condition, location and depth of burial of the cables in order to continuously support Hainan Island. This survey is an unprecedented challenge each year as the power supply needs to be turned off in order successfully survey, as well as being influenced by a number of pressures and factors. Traditionally, this survey work has been undertaken using tone injection systems alongside sub-bottom profilers so a seafloor map could be produced. The operation of this set equipment means that the cables could not be surveyed whilst powered but in turning the power off, the island is at great risk should any faults occur in the main power supply.

Qiongzhou Strait; Leizhou Peninsula and Hainan Island

(The Fukang Line of subsea cables runs from mainland China across the Qiongzhou Strait to Hainan Island)

HydroPACT 350 Successfully Tested for Live Submarine Cable Surveys, Proving Accuracy and Reliability

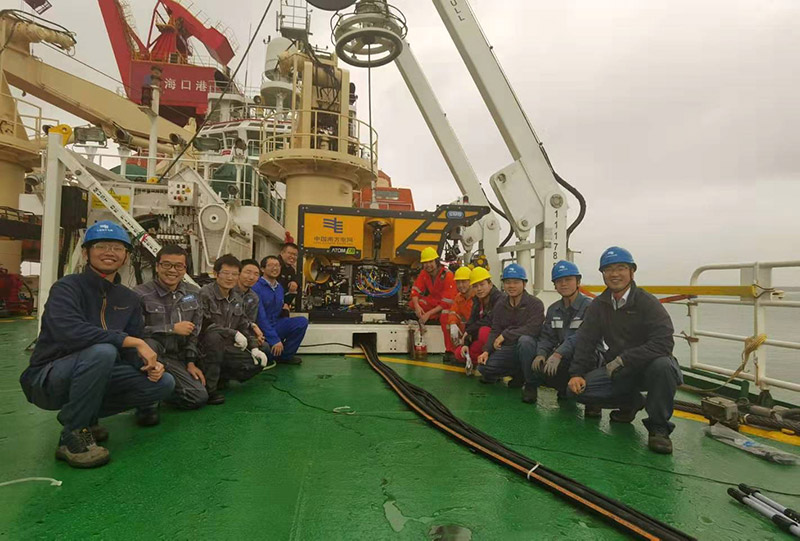

In order for the end-user to adopt this new survey approach, and to be able to survey the cables whilst live, a trial was necessary to test the equipment so that it could be verified for performance and so that a blueprint could be established. China ORE, Qingdao Ocean Research Equipment Ltd and EHV Power Transmission Company successfully conducted a field test process of submarine cable under live conditions. During what was affectively a FAT (Factory Acceptance Test), the HydroPACT 350 system was fitted to the bow of a small surface craft in order to conduct the survey. ‘The new 350 system worked well’, said Jerry Li Mingbo. ‘It was able to lock onto the live (500kv power supply) cables and surveyed depth of burial within the specified accuracies’.

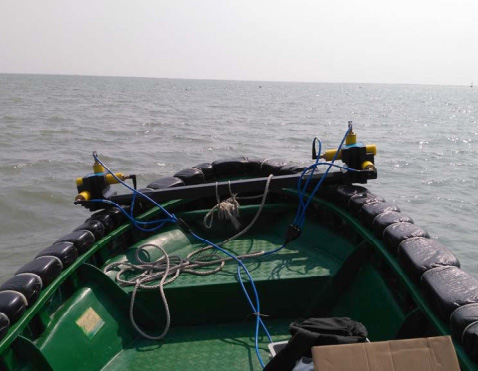

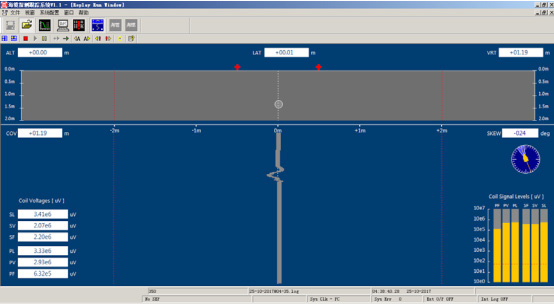

The operation started with a land test along a coastal road with buried cable. After some inteference deemed by experts to be coming from nearby wind turbines, the trial moved to the ebb tide zone for the next phase. The 350 coils successfully measured and delivered location and depth of burial data back to the ‘topside’ SDC (Surface Display Computer) unit. The trial then moved onto ocean waters as the survey officers rented a small surface craft to use in the near shore segment of the sea where, whilst in tracking mode, the 350 system interface gradually showed the 3-phase cable that was being surveyed. After a number phases, the testing concluded to show that the 350 can well-receive the electromagnetic field generated by the cable signal.

The operation started with a land test along a coastal road with buried cable. After some inteference deemed by experts to be coming from nearby wind turbines, the trial moved to the ebb tide zone for the next phase. The 350 coils successfully measured and delivered location and depth of burial data back to the ‘topside’ SDC (Surface Display Computer) unit. The trial then moved onto ocean waters as the survey officers rented a small surface craft to use in the near shore segment of the sea where, whilst in tracking mode, the 350 system interface gradually showed the 3-phase cable that was being surveyed. After a number phases, the testing concluded to show that the 350 can well-receive the electromagnetic field generated by the cable signal.

To further verify the measurement accuracy of the 350 system, three random locations were chosen for routing and buried depth detection. After again attaining the required data for these cable assets, the trial was deemed a great success delivering two key insights. One, the device can normally receive the electromagnetic field generated by the submarine cable under the charged state, and two, the 350’s response to high sensitivity and ability to detect in such conditions meant that it met the requirements for surveying the Hainan Network System. Power data for the Fukang Line also matched the 350’s output and showed that whilst powered, the line could be surveyed.

HydroPACT 350 Revolutionizes Fukang Line Surveying by Enabling Power-on Inspections, Eliminating Complex Power-off Scheduling

The main advantage in ultising the 350 system is that the cable survey can now be undertaken with the cables still powered eliminating the need to organise a power-off operation. Any window of power-off needs to coincide with appropriate survey weather that requires in-depth scheduling (and a bit of weather luck!) which all equates to one huge logistical undertake. As well as the weather, a survey vessel, a survey team, the power company, Hainan Island and its inhabitants, businesses, hospitals and homes have to be considered and aligned in order to even set a time and date for the Fukang Line to be switched off. All must be notified, unified and in agreement in order prohibit power for cable survey and maintenance. Being able to survey the Fukang Line whilst still powered eliminates this whole complex task, easing logical considerations and allowing for a repeatable process.

The main advantage in ultising the 350 system is that the cable survey can now be undertaken with the cables still powered eliminating the need to organise a power-off operation. Any window of power-off needs to coincide with appropriate survey weather that requires in-depth scheduling (and a bit of weather luck!) which all equates to one huge logistical undertake. As well as the weather, a survey vessel, a survey team, the power company, Hainan Island and its inhabitants, businesses, hospitals and homes have to be considered and aligned in order to even set a time and date for the Fukang Line to be switched off. All must be notified, unified and in agreement in order prohibit power for cable survey and maintenance. Being able to survey the Fukang Line whilst still powered eliminates this whole complex task, easing logical considerations and allowing for a repeatable process.

Whilst China ORE were conducting the test operations, they utilised the SDC for displaying the DeepView software. This shows the various types of location, skew angle and depth of burial data that the system records.

After a number of phases of testing, including land and offshore environments, the HydroPACT 350 passed the acceptance standards.

As a result, China ORE supplied the HydroPACT 350 to EHV Power Transmission Company permanently for future use. The system successfully completed the field test, providing reliable, informative and accurate survey data. All parties agreed that the 500kv Fukang Line submarine network of cables should be surveyed with the now approved 350 system and should be done so still powered because the equipment’s performance and depth detection successfully completed final acceptance and passed the acceptance test.

Now the de facto method in surveying the Fukang Line, the annual survey can be done at any time because the 350 system is capable of tracking the cables whilst still powered. The requirement to unpower these cables for root survey is now eliminated.

|

|

|

Phase 1 set up

| Phase 2 set up

| Phase 2 monitoring

|

HydroPACT 350 System Streamlines Fukang Line Surveys, Offering Greater Flexibility and Cost Savings for EHV Power Transmission

Through China ORE, who supplied the HydroPACT 350 for the trial and then onto EHV Power Transmission Company, the need to survey the Fukang Line power cables whilst still powered has been met. Surveyors can now survey the line without having to organise the complex power-off operation, simplifying the process ten-fold.

‘This new cable tracking system brings us so many benefits and it will be integrated onto our new SMD ROV system’, said Mr Zhoujing, Chief Engineer of Operation and Maintenance Department, EHV Power Transmission Company. ‘ This means we can now do the route survey according to our own schedule by ourselves, this saves us a lot of money and a lot of time, enabling us to ensure the health and safety of the submarine cable operation.’

The huge pressure that has traditionally come with survey project has now loosened with the use of the Teledyne TSS HydroPACT 350 system. The key advantage for EHV Power Transmission Company is that they do not need to survey whilst the cables are unpowered, meaning that Hainan Island will not be at risk of no back up power. They too can now undertaken each year’s survey work according to their own schedule, providing more project and time flexibility than ever before.

Jerry Li Mingbo of China ORE described the trial as ‘a great success’ and is ‘happy to have contributed to Hainan Island’s infrastructure maintenance to such degree’. China ORE remain as EHV Power Tranmission Company’s first point of contact for system support and maintenance, prior to any further support from Teledyne TSS.